English

English

About Us

Who We Are

Following the brand's concept of "comfort and health", Jabra Sanitary specializes in improving bathrooms using advanced technology.

With over 20 years of innovation in bathroom

products, we annually produce over 2 million

items, distributed in more than 190 countries.

We are dedicated to upgrading your

bathroom for a better life.

20+

year

Focusing on the bathroom industry

50+

Product Patent

200,000

Square Meters of Factory

2M+

PCs produced every year

20

High-Pressure Slip Casting Lines

190+

Exported Countries

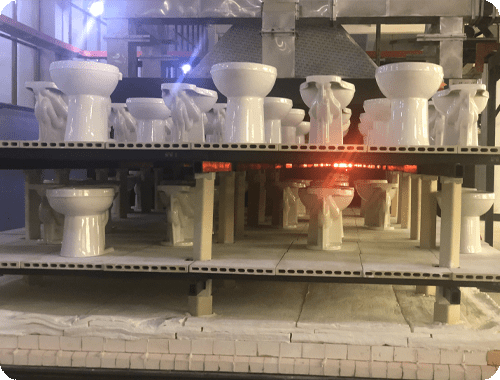

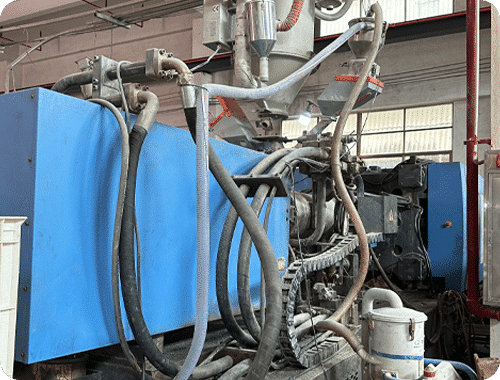

Our Manufacturing Advantages

Jabra Sanitary excels in manufacturing due to our high-quality materials, advanced automated equipment, and efficient production methods.

Quality Raw Materials

Thanks to the rich natural resources in our hometown, we have the ability to make great ceramic bathroom items with high-grade clay.

We also have strong connections with raw material suppliers.

Fully Automatic Machines

We started using new high-pressure molding machines, which produces four times faster than before.

With automatic shuttle kilns and automatic casting machines, we are able to develop all sorts of ceramic products in different styles.

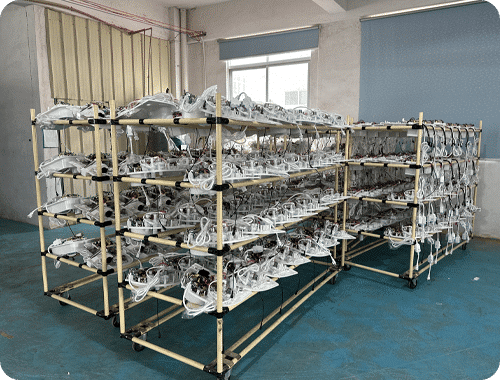

Efficient Production Lines

We operate 20 high-pressure slip-casting lines for basin and toilet production simultaneously.

This setup not only enhances our production capacity but also reduces the costs of each product.

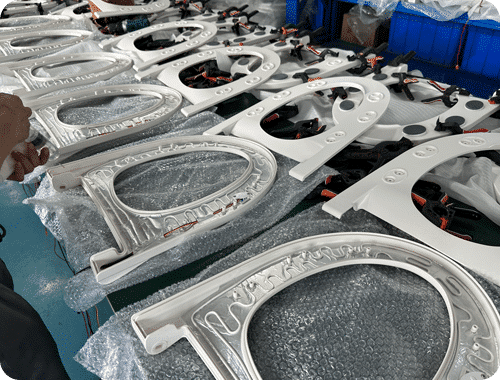

Our Production Process

Our Cutting-edge Technology

Jabra Sanitary has a big Research and

Development(R&D) team of 200 engineers.

They focus on innovation, functionality,

and sustainability in every product design.

Every year, we release over 10 kinds of new products to fulfill customer's new needs. We promise every product is equipped with leading core chip technology for superior intelligent bathing and kitchen experiences.

Infrared Sensor

Capacitive Sensing

Intelligent Temperature Control System

Microwave Radar Sensor

Hydroelectricity

Magnetic Sensor

Looking for a one-stop solution for bulk toilet purchasing?

Tell us your needed quantity and style. We will send you a custom quote for your bathroom project.

Tell us your needed quantity and style. We will send you a custom quote for your bathroom project.

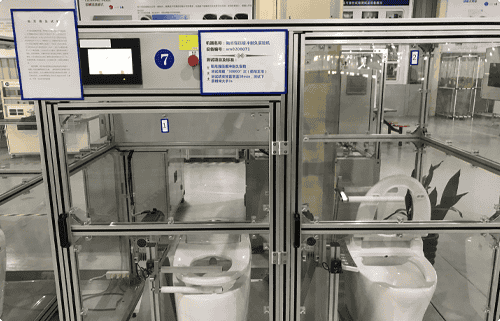

100% Quality Control

Jabra Sanitary checks the quality of our products very carefully at every step,

making sure everything is 100% good before it's finished.

High-Quality Raw Materials

At Jabra, we use top-quality clay and high-tech machines to make our ceramic products. We also focus on protecting the environment and saving water to make sure our products are really high quality.

Global Standards

Our products are top-notch because we use great manufacturing techniques. We meet international standards and have certificates for different markets to make sure you get the quality you need.

Rigorous Testing

We do lots of different strict checks like checking how things flow, handling salt, pressure, blasts, how long they last, how they deal with shaking, and different temperatures and wetness.

Excellent Customer Service

Jabra Sanitary is really dedicated to great customer service

and does a lot to make sure customers are happy.

Quick Response

Efficient handling of all inquiries.

One-Stop Solution

Comprehensive bathroom solutions.

Efficient Lead Times

Optimal inventory for timely delivery.

Eco-Friendly Packaging

Sturdy, sustainable materials.

Reliable Warranty

Two years coverage for product faults.

Low MOQ & Durability

MOQ is 10 PCs and 500,000 durability tests.

Patent and Certificates

For the past 20 years, we've earned numerous awards for design and innovation. With over 2,000 brand stores worldwide, we've gained a large base of loyal customers.

We distribute our products in over 190 countries and hold essential certifications that meet global standards.

Why Choose Jabra

We're your trusted sanitary ware supplier for water closets, flush toilet bowls, smart toilets, or other sanitaryware in China.

Low MOQ

Test 10 pieces to learn customer

preferences

High Durability

Products endure 500,000 tests longevity

Competitive Price

Prices are 30% lower, with no added markups

Unmatched Efficiency

40% faster delivery than competitors

Reduced Risk

One-stop service reduces risk by 60%

Warranty Policy

Two years warranty for non-user faults

We Have Social Responsibility!

Most importantly, Jabra Sanitary takes social

responsibility seriously, as a top company caring

about the environment.

We focus on making bathroom products that save energy

and are eco-friendly, to reduce our impact on the

environment as much as we can. We use technology

to tackle global environmental challenges.

For example, we use materials from farmed renewable

sources. We also recycle most of the waste, and we

follow EC regulations on Packaging Waste.