English

English

Manufacturing

Who We Are

With over 20 years of innovation in bathroom products, we annually produce over 2 million items, distributed in more than 190 countries. We are dedicated to upgrading your bathroom for a better life.

Our Factory Strengths

Our factory excels with advanced machines and a skilled team, ensuring top-quality production.

Looking for a one-stop solution for bulk toilet purchasing?

Tell us your needed quantity and style. We will send you a custom

quote for your bathroom project.

Our Manufacturing Advantages

Jabra Sanitary excels in manufacturing due to our high-quality materials,

advanced automated equipment, and efficient production methods.

-

Quality Raw Materials

Thanks to the rich natural resources in our hometown, we have the ability to make great ceramic bathroom items with high-grade clay.

We also have strong connections with raw material suppliers.

-

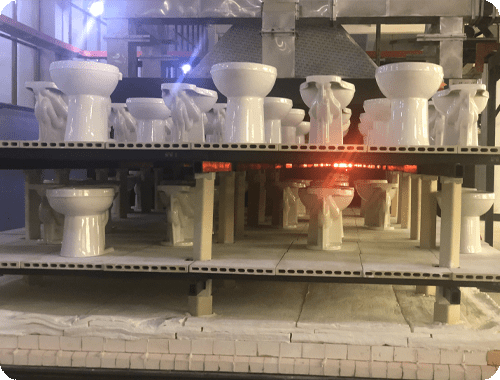

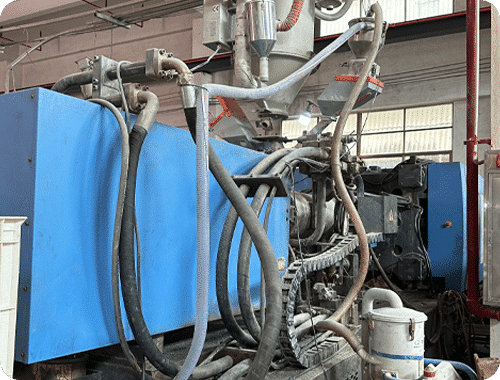

Fully Automatic Machines

We started using new high-pressure molding machines, which produce four times faster than before.

With automatic shuttle kilns and automatic casting machines, we are able to develop all sorts of ceramic products in different styles.

-

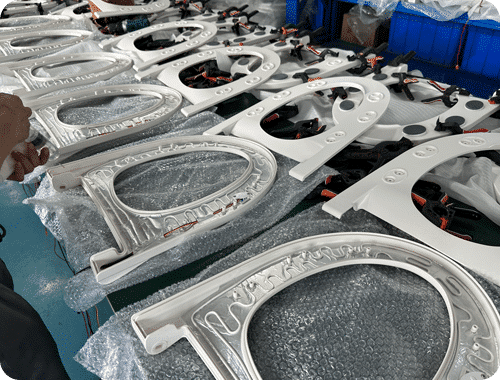

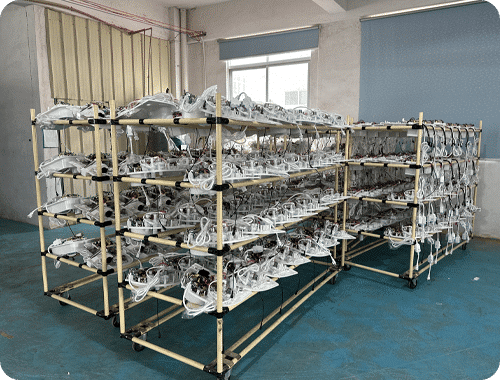

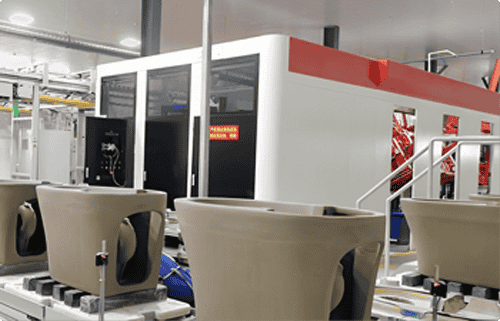

Efficient Production Lines

We operate 20 high-pressure slip-casting lines for basin and toilet production simultaneously.

This setup not only enhances our production capacity but also reduces the costs of each product.