English

English

Jabra Sanitary is a sanitaryware supplier offering toilets, sinks, faucets, bathtubs, etc., at competitive prices. If you're a distributor, wholesaler, or project contractor, get a quote today!

$23.9 Limited-time Offer

$23.9 Limited-time Offer Consignment Policy

Consignment Policy 20 Years of Experience

20 Years of Experience

Did you know 70% of Japanese households use smart toilet seats? At their core, they're about making our lives easier, cleaner, and a little more luxurious.

But have you ever stopped to think about how these high-tech wonders come to life? That's exactly what we're here to explore—the fascinating toilet seat manufacturing process behind smart toilet seat covers.

We'll walk you through every step—starting with the market trends pushing their popularity, the materials that make them tough and safe, and the detailed production process that brings them together.

Table of Contents

Market Trends Driving Demand for Smart Toilet Seat Covers

Common Materials Used in Smart Toilet Seat Cover Production

Step-by-Step Smart Toilet Seat Cover Production Process

Integrating IoT and Sensors: From Bidet Controls to Health Diagnostics

Key Challenges in Manufacturing Smart Toilet Seat Covers

Quality Testing Protocols: Ensuring Reliability and Safety

Compliance Standards: Navigating FDA and FCC Certifications

Sustainability in Production: Eco-Friendly Materials and Processes

Cost Optimization Strategies for Toilet Seat Cover Manufacturers

Smart Toilet Seat Cover Innovations: AI, Health Tech, and Beyond

FAQs

Conclusion

Market Trends Driving Demand for Smart Toilet Seat Covers

Smart toilet seat covers are popping up everywhere, and it's no accident. Three big trends stand out as the driving forces behind this surge: aging populations, the rise of luxury smart homes, and regional leaders paving the way.

Aging Populations: Comfort Meets Necessity

First up, the world's getting older. By 2050, 1.5 billion people will be over 65. That's where smart toilet seat covers shine.

For elderly folks, these features aren't just convenient—they're game-changers for staying independent. As families search for ways to support aging loved ones, demand for these products is soaring, and we're excited to see how they're making lives better.

Luxury Smart Homes: Tech-Savvy Living

Next, luxury smart homes are taking off, and smart toilet seat covers are right at home in them. These covers are part of the bigger home automation wave—think lights, thermostats, and now toilets, all controlled with a smartphone app or a quick voice command.

For tech-savvy homeowners and luxury buffs, these covers aren't just practical; they're a stylish upgrade. As smart homes become the norm, we're betting these high-tech bathroom additions will too.

Regional Leaders: Showing the Way

Finally, some regions are ahead of the curve. Take Japan and South Korea—smart toilet seat covers are practically standard there, thanks to a love for cleanliness and advanced tech. Features like water-saving bidets fit their cultural vibe perfectly.

Meanwhile, in Europe, eco-friendly policies are nudging people toward these products. Economic strength and tech-friendly cultures are fueling this trend, and we're watching it spread.

Common Materials Used in Smart Toilet Seat Cover Production

Smart toilet seat covers are more than just fancy gadgets—they're built from materials designed for safety, durability, and comfort. Every component, from the seat to the nozzles, is carefully selected to perform under daily use.

Antimicrobial ABS/PP: Resisting Bacterial Growth

The main body of most smart toilet seat covers is made from antimicrobial ABS (acrylonitrile butadiene styrene) or PP (polypropylene). These plastics are tough, lightweight, and perfect for shaping through injection molding.

What sets them apart? They're treated to resist bacteria, making them a hygienic choice for something we use every day.

Medical-Grade Stainless Steel for Bidet Nozzles

Next up are the bidet nozzles, which rely on medical-grade FDA-approved stainless steel. This isn't your average metal—it's rust-proof, corrosion-resistant, and built to withstand constant water exposure.

It is renowned for its durability and hygiene, noting that toilet seat cover manufacturers choose it to ensure the nozzles stay clean and reliable over time.

Silicone Gaskets: Ensuring Waterproofing

Finally, silicone gaskets play a crucial role in keeping everything watertight. These flexible seals sit between components, protecting the electronics from water damage.

Silicone boasts heat resistance and durability, making it ideal for the steamy, wet bathroom environment. Without these gaskets, leaks or short-circuits could ruin the experience.

Step-by-Step Smart Toilet Seat Cover Production Process

Now that we've covered the materials, let's dive into how these components come together in the toilet seat manufacturing process.

From molding the plastic to integrating the software, each step is crucial for creating a reliable and high-tech smart toilet seat cover.

Injection Molding: Shaping the Foundation

The process kicks off with injection molding. Here, antimicrobial ABS or PP plastic is heated until it's pliable, then injected into a mold to form the seat's shape.

This step ensures every seat is consistent, durable, and built to last. It's the foundation that sets the stage for everything that follows.

Vibration Welding: Joining the Pieces

Next, we move to vibration welding, where the molded parts are fused. High-frequency vibrations generate friction between the plastic pieces, melting them just enough to create a strong, seamless bond.

This technique makes the seat sturdy and water-tight—crucial for a product that combines electronics and water.

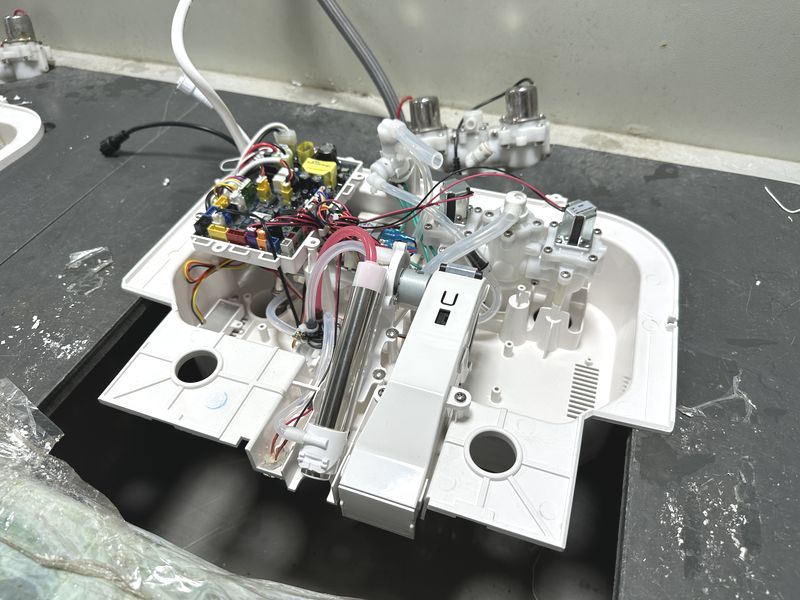

Electronics Assembly: Adding the Smart Features

Here's where the real magic happens—electronics assembly. Sensors, heating elements, and bidet controls are carefully installed and connected.

Each piece must be perfectly positioned to ensure the seat functions flawlessly. This step transforms a simple plastic cover into a smart device, and precision is key to avoid any hiccups down the line.

Software Integration: Programming the Magic

With the hardware set, it's time for software integration. The control unit is loaded with software that lets you tweak settings like water temperature or seat warmth. This stage includes rigorous testing to eliminate bugs, ensuring a smooth and user-friendly experience.

Laser Engraving: The Finishing Touch

Finally, laser engraving adds the polished details—logos, model numbers, or designs. Using precise lasers, toilet seat cover manufacturers etch these onto the plastic without harming the surface.

It's a clean, professional finish that makes the product look as great as it performs.

Integrating IoT and Sensors: From Bidet Controls to Health Diagnostics

Smart toilet seat covers have evolved far beyond their basic purpose, becoming sophisticated devices that blend comfort, hygiene, and cutting-edge technology.

What Are IoT and Sensors in Smart Toilet Seat Covers?

The Internet of Things (IoT) connects devices to the internet, allowing them to collect and exchange data seamlessly. In the context of smart toilet seat covers, IoT works hand-in-hand with sensors—tiny, sensitive components that detect changes in their environment.

These sensors act as the system's "eyes and ears," gathering data like occupancy, temperature, or even biological markers. During manufacturing, these elements are carefully embedded into the seat's design, ensuring durability, precision, and connectivity.

Bidet Controls: Precision and Personalization

One standout feature of smart toilet seat covers is their advanced bidet functionality, made possible by IoT and sensor integration. Here's how this works in practice:

- Automatic Activation: Sensors detect when someone is seated and trigger the bidet function automatically. This touch-free operation enhances hygiene and simplifies use, as the system responds without manual input.

- Customizable Settings: IoT connectivity allows users to fine-tune bidet settings—such as water temperature, pressure, and nozzle position—via a smartphone app or remote interface. Manufacturers integrate wireless modules during production to enable this seamless communication.

- Remote Monitoring: Built-in IoT systems can send alerts about maintenance needs or usage patterns, ensuring the bidet remains reliable over time.

Ads

Ads

Japanese Bidet Smart Toilet Seat

Experience enhanced comfort and advanced technology with the Japanese Toilet Bidet With Dryer J-1033, designed to elevate your bathroom routine.

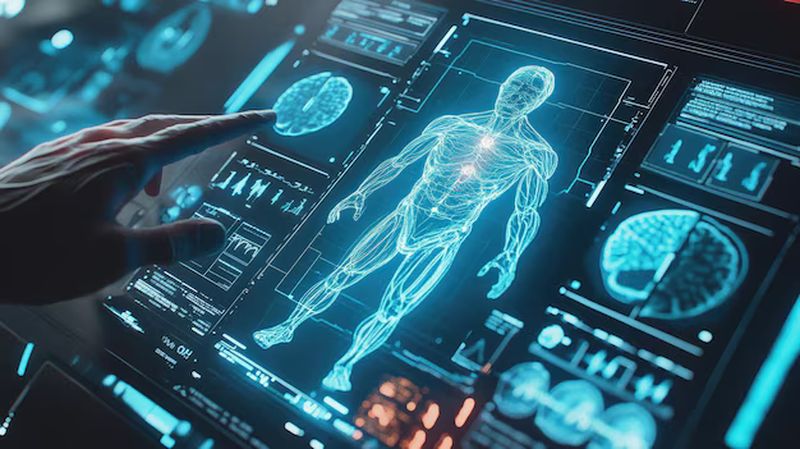

Health Diagnostics: A New Frontier

Perhaps the most revolutionary aspect of smart toilet seat covers is their ability to monitor health. For example, Jabra collaborates with Mayo Clinic. Sensors embedded during toilet seat manufacturing enable the following:

- Vital Sign Tracking: Sensors can measure heart rate, body temperature, or weight with every use. These components are strategically placed in the seat's contact points and calibrated to provide accurate, consistent readings.

- Urine and Stool Analysis: Emerging designs incorporate sensors capable of analyzing waste for signs of dehydration, infections, or other abnormalities. This requires advanced biochemical sensors, integrated into the seat or bowl area, and rigorous testing during production to ensure reliability.

- Data Sharing: IoT connectivity allows this health data to be securely transmitted to healthcare providers or logged in a user's app. IoT reduces water waste by 20%. Toilet seat cover manufacturers must install encrypted communication systems to protect privacy.

Key Challenges in Manufacturing Smart Toilet Seat Covers

Manufacturing smart toilet seat covers is no easy feat. These high-tech devices combine electronics, water systems, and advanced materials, which means there are plenty of opportunities for things to go wrong.

Waterproofing Failures: Keeping Water Where It Belongs

Smart toilet seat covers operate in wet environments, but water and electronics are a risky combination. If water seeps into internal components, it can cause short circuits, corrosion, or complete device failure. Waterproofing, therefore, is a critical concern for toilet seat cover manufacturers.

Firmware Bugs: Ensuring Smooth Operation

Firmware is the software that powers the smart features of toilet seat covers—think bidet controls, sensors, and connectivity. But like any software, it's prone to bugs, which are errors that can make the device act unpredictably.

Supply Chain Delays: Managing Component Shortages

Smart toilet seat covers depend on specialized components, like medical-grade nozzles for bidet functions. These nozzles must meet high standards for hygiene and durability, often limiting manufacturers to specific suppliers.

But supply chains aren't always reliable. Delays can stem from global shipping problems, raw material shortages, or bottlenecks at the supplier's end, leading to longer lead times for these critical parts.

When a key component like a nozzle is delayed, it can bring the whole toilet seat production line to a standstill. This disrupts schedules, drives up costs (think expedited shipping), and makes it harder to meet demand.

Quality Testing Protocols: Ensuring Reliability and Safety

When you invest in a smart toilet seat cover, you expect it to be more than just a high-tech gadget—it needs to be tough, waterproof, and safe for everyday use. To make that happen, toilet seat cover manufacturers put these products through a series of rigorous quality tests following IP67 testing protocol.

Durability: Built to Handle Daily Use

Smart toilet seat covers face constant action: opening and closing, button presses, and bidet activations, day after day. To ensure they can take the punishment, manufacturers test their durability with methods designed to mimic years of use in a condensed timeframe.

- Mechanical Stress Testing: Robotic arms simulate thousands of cycles by repeatedly lifting and lowering the seat, pressing buttons, and triggering features like the bidet. It's like slamming a car door over and over to confirm it won't give out after a few years.

- Material Strength Checks: The seat's plastic and metal parts are subjected to pressure and impact tests to check for cracks, fading, or warping. This ensures the product can withstand heavy sitters or accidental bumps without falling apart.

Water Resistance: Keeping the Electronics Dry

Bathrooms are notoriously wet, and with electronics packed into smart toilet seat covers, water resistance is a must. Manufacturers use specialized tests to ensure water stays out and the tech stays functional.

- Spray and Submersion Tests: Seats are blasted with water sprays from multiple angles or even dunked underwater to check for leaks. This confirms that splashes from a shower or sink won't ruin the system.

- Humidity Exposure: Products are placed in humidity chambers that replicate steamy bathroom conditions over time. This ensures moisture doesn't slowly seep into the electronics, causing corrosion or malfunctions down the line.

Electrical Safety: Protecting You from Shocks and Hazards

With features like heated seats and electronic bidet controls, electricity is a big part of the smart toilet seat experience. That makes electrical safety critical. Manufacturers take extra steps to eliminate risks like shocks or fires.

- Grounding and Insulation Checks: Every wire, connection, and component is tested to ensure proper grounding and insulation. This keeps electricity contained, so you never feel a zap where you least expect it.

- Compliance with Safety Standards: Products are rigorously evaluated to meet certifications like UL (Underwriters Laboratories) or ETL (Intertek). These standards involve inspecting the power supply, wiring, and heating elements to confirm they're safe for a wet setting.

Compliance Standards: Navigating FDA and FCC Certifications

Making sure our smart toilet seat covers meet strict compliance standards is a big part of what we do at Jabra Sanitary. These standards come from organizations like the FDA and FCC systems, and they ensure toilet seat manufacturing is safe, reliable, and ready for your bathroom.

FDA Certification: Keeping Health Features Safe

Let's kick things off with the FDA, or Food and Drug Administration. You might think, "Wait, isn't that about food and medicine?" You're right, but it also covers medical devices. Some of our smart toilet seat covers have cool health features—like tracking your weight or checking your waste for health clues.

When we add those, our products might count as medical devices, so they need FDA approval.

FCC Certification: Making Wireless Work Smoothly

Next up is the FCC, or Federal Communications Commission. This group makes sure electronic gadgets that use wireless signals—like our smart toilet seat covers—play nice with other devices. Since many of our products connect to your phone or smart home with IoT modules, FCC rules are super important.

We test our toilet seats in special labs to check they don't send out weird signals that could mess with your Wi-Fi or TV. These invisible waves (called electromagnetic radiation) need to stay at safe levels. Passing FCC tests means our products won't cause trouble and work smoothly with all your tech.

Sustainability in Production: Eco-Friendly Materials and Processes

Sustainability might sound like a fancy term, but it's simple: we're building products that work great for you while looking out for the Earth's future.

Recycled ABS Plastic: Turning Old into New

We're proud to use recycled ABS plastic (30% recycled ABS per unit) in our smart toilet seat covers. By recycling, we lower our impact and keep landfills a little emptier. And don't worry: recycled ABS is just as strong and long-lasting as the new stuff, so you get a high-quality seat that's eco-friendly too.

Energy Efficiency: Powering Up with the Sun

We're also serious about saving energy. Our factories run partly on solar panels, soaking up the sun to power production. This reduces our need for fossil fuels, which means cleaner air for everyone.

Plus, we use smart machines that only draw power when necessary—think of them like lights that switch off when you leave the room.

We're even tackling water use. In places where water is scarce, every drop counts.

Modular Design: Fix It, Don't Toss It

Ever had to ditch a broken gadget because it couldn't be fixed? We hate that too. That's why our toilet seat covers feature a modular design. They're built with parts you can swap out or upgrade. If something breaks, you replace just that piece—not the whole seat.

Cost Optimization Strategies for Toilet Seat Cover Manufacturers

We're committed to delivering top-notch smart toilet seat covers while keeping them affordable. How do we do that? By optimizing our toilet seat manufacturing costs in clever ways—without ever skimping on quality.

Breaking Down the Costs

To understand how we save, it's worth knowing where our costs come from. Here's the breakdown for toilet seat production:

- Electronics (50%): This covers the high-tech stuff—sensors, IoT modules, and bidet controls. It's the biggest chunk of our expenses.

- Molds (20%): We use injection molding to shape the plastic, and creating those molds isn't cheap.

- Labor (15%): Our team assembles the seats and integrates the electronics.

- Compliance (10%): Meeting FDA, FCC, and IP standards requires testing and documentation.

Smart Savings Tactics

Here's where the magic happens. We use these strategies to keep costs down:

- Bulk Sourcing Sensors: Since electronics are our biggest expense, we buy sensors in bulk. Bulk sourcing reducessensor costs by 20%.

- Automated Vibration Welding: It's faster, more consistent, and reduces the need for manual labor—saving time and money.

Smart Toilet Seat Cover Innovations: AI, Health Tech, and Beyond

Advancements—AI diagnostics, voice control, and 3D-printed customization—are making everyday routines smarter, healthier, and more tailored to you.

AI Diagnostics: A Health Boost from Your Seat

What if your toilet could keep an eye on your health? With AI diagnostics, it can! These smart seats analyze waste to detect things like dehydration or early illness signs—think of it as a quick health scan while you sit.

Voice Control: Talk to Your Toilet

Imagine adjusting your seat without touching a thing. Voice control lets you say, "Warm the seat" or "Start the bidet," and it happens—hands-free! Whether you're multitasking or just love convenience, this feature makes your bathroom feel futuristic.

3D-Printed Customization: Your Style, Your Fit

With 3D-printed customization, your toilet seat can match your vibe. Pick the shape, color, or add extras like cushioning—all custom-made. It's sustainable too, with zero material surplus.

FAQs

In this section, we'll tackle the most common questions people have about these high-tech bathroom upgrades.

What does a smart toilet seat do?

- Heated seats: Say goodbye to chilly mornings with a seat that warms up for you.

- Bidet functions: These use water to clean you after you go, offering a gentler and more thorough option than toilet paper alone.

- Automatic opening and closing: The lid lifts when you approach and lowers when you're done—no touching required.

- Deodorizers: Built-in systems zap away bad smells, keeping the air fresh.

- Night lights: Soft lighting helps you find your way in the dark without flipping on bright lights.

- Health monitoring: Some fancy models can even check things like your weight or hydration levels.

How do automatic toilet covers work?

- Sensors: They've got motion or proximity sensors that know when you're near.

- Opening: As you walk up, the sensor tells the lid to pop open automatically.

- Closing: When you step away after using it, the sensor triggers the lid to close on its own.

Are toilet seat lid covers sanitary?

Toilet seat lid covers can boost bathroom hygiene, but they're not a cure-all.

How do you clean a smart toilet seat?

- Power off: Unplug it or switch off the electricity to stay safe and protect the electronics.

- Gentle wipe: Use a soft, damp cloth to clean the seat and lid—don't drench it.

- Skip harsh stuff: Avoid bleach or scratchy cleaners that could mess up the surface or sensors.

- Check the manual: Every model's a bit different, so follow the maker's tips, especially for bidet parts.

What's the correct way to use a toilet seat cover?

- Grab one: Pull a cover from its pack and unfold it.

- Lay it down: Place it on the seat so the flap dips into the bowl.

- Sit: Settle in, making sure it doesn't slide off.

- Flush: When you're done, it'll flush away with everything else.

Conclusion

How to make a toilet seat? The toilet seat manufacturing is a complex yet fascinating journey from materials selection to the integration of advanced technology.

As this trend continues to rise, choosing the right brand can make all the difference. Jabra Sanitary stands out as a leader in the smart bathroom industry. With a commitment to both technology and hygiene, Jabra offers products that are reliable, long-lasting, and designed to fit seamlessly into your smart home lifestyle. Join 500,000+ satisfied users!